LED light power supply – input, output and other specifications

Taylor

Introduction

When it comes to LED lamps, we often think of its wattage, light efficiency, long lifetime, and the various functions that LED lamps can achieve, etc. In fact, these are closely related to LED light power supply(LED driver). For example, the maximum output power of the LED driver, then the wattage of the LED module is basically within this range. The luminous efficiency of LED lamps is also greatly affected by the LED driver. A high-efficiency LED driver can make the lamp have higher luminous efficiency, anyway. Similarly, some special functions that LED lamps need to implement, such as dimming, timer dimming, CLO, NTC and Zhaga D4i, are closely related to the LED light power supply used. If the LED driver does not support the corresponding functions, the LED lamps cannot achieve the above functions. Therefore, learning the knowledge related to LED light power supply can help us better and faster select the LED driver suitable for our LED lamps. For example, if customers need our lamps to achieve corresponding functions, we can recommend suitable power solutions to our customers. When customers do not understand the corresponding functions and cannot make reasonable judgments, we can help customers analyze these functions to help them make choices, etc.

What’s LED light power supply?

The LED modules of LED lamps cannot be directly connected to 220V AC. LED lamps require a power supply device to convert AC into DC (voltage and current) to ensure that the LED lamps work properly. In simple terms, LED light power supply is a device that converts external power into voltage and current suitable for the operation of LED light-emitting diodes. In addition to the basic functions of voltage conversion and current limiting, the LED power supply also has protection functions, dimming functions and other auxiliary functions. Protection function means that the power supply can provide overvoltage, undervoltage, overcurrent, overheating and short circuit protection to ensure the safety of lamps and power circuits. The dimming function refers to 0-10V, Dali, timer dimming and other functions(wireless control). ZGSM believes that when selecting a LED light power supply, you need to give priority to factors such as input voltage range, output voltage and current, efficiency, operating temperature range, and safety certification to ensure its compatibility and reliability with LED lamps. On this basis, we will consider other functions, such as dimming, timer dimming, CLO, intelligent control, Zhaga and NEMA connections.

Main parameters of LED light power supply

Input specifications of LED lighting power supply

Input voltage: the AC input voltage range of the driver should be consistent with the voltage of the grid. Voltage changes should also be taken into account. For example, a 90-305 VAC LED light power supply can be used in both 120 and 220 VAC power grid systems, such as Europe and Japan. For the voltage in American, the voltage in some areas is 347VAC. At this time, the 90-305VAC LED driver cannot be used. Instead, an LED driver with 249-528VAC input should be used in these areas.

Power factor and THD: Power Factor (PF) is a measure of the efficiency of power utilization of electrical energy. It represents the ratio between actual power and apparent power. When it is close to 1, it means that the electrical energy in the circuit is effectively utilized. In LED lamps, this value is often 0.95 – 0.99. Total Harmonic Distortion (THD) measures the difference between the power supply output waveform and the ideal sine wave. A low THD value means that the output waveform is closer to the ideal, which helps to reduce energy loss and system interference. Usually LED light power supply’s THD is around 10%, ideally <5%. LED drivers are usually designed with high power factor and low total harmonic distortion to improve power efficiency, stability and reliability.

IEC electrical protection classes: A classification system for electrical equipment’s level of protection against electric shock, often referred to as insulation level or protection level. This classification system describes the ability of electrical equipment to protect against electrical shock hazards, including how to reduce and prevent hazards caused by current and voltage. There are three approved protection classes: Protection class l is for lights which require a protective conductor connection(grounding); Protection class ll refers to increased protective insulation without a separate protective conductor connection; Lights(such as solar street lights) operated with safety extra-low voltage are assigned to protection class lll. LED lights with 24v DC supply voltage have the electrical protection class lll which is with safety extra-low voltage (SELV). This means that the supply voltage is so low that there is no danger of electric shock. For LED lights with 220- 240V AC or 90-305V AC supply voltages, all electrically conductive housing parts are connected to the protective conductor system of the fixed electrical installation, which is earthed(Class I) or double insulated(Class II).

Output specifications of LED lighting power supply

Voltage range: As we said before, LED light power supply can convert external alternating current (AC) into direct current (DC) suitable for LED operation. One of the important parameters involved is the voltage range. The voltage output range of the LED power supply is usually between tens of volts and hundreds of volts, which determines whether the LED driver can adapt to the LED module. There is another concept here, which is the forward voltage of the LED chips. This parameter is described in the photoelectric characteristics of the LED chips and is defined as the voltage required to turn on the LED. For details, please refer to the specification sheet of the LED chips. Different numbers of LED chips are connected in different series and parallel ways to form an LED module, and its forward voltage range will vary greatly. Therefore the forward voltage in the LED fixture should match the output voltage of the selected power supply. In addition, the operating voltage may vary slightly depending on the driving current, which is also a factor we need to consider.

Current range: LED light power supply is divided into two different types: constant voltage source and constant current source. Among LED outdoor lamps, constant current source LED drivers are often used, and their output current remains constant when the load resistance changes. In other words, no matter how the load resistance changes, the constant current source will try to keep the output current constant, which can avoid damage to the LED chips caused by excessive current. The light output of an LED is directly proportional to the selected drive current, but the light efficiency is inversely proportional to the selected drive current. In practical applications, we should make selections based on the recommended driving current of LED chips as well as appropriate high lumen output(but normally bad heat dissipation) and light efficiency of the lamp.

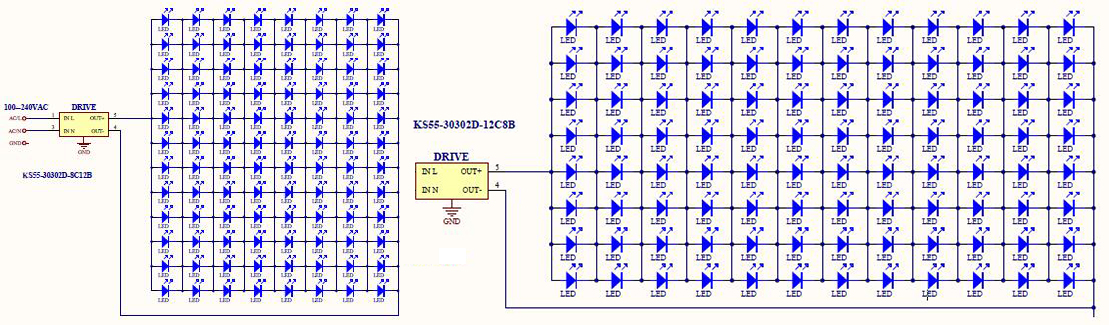

LED Arrays: In many cases, LEDs can be configured in series or parallel arrays to meet application needs. If a group of products needs to be driven by the same power supply, information about series/parallel combinations of LED chips is important. Voltages are to be added in series and currents should be added when LEDs are connected in parallel. The total voltage and current requirements of the module need to be known in order to power up the module. The product of voltage and current is the wattage of the LED module, which needs to match the maximum wattage of the LED light power supply. The following is the series combination diagram of ZGSM street lights. If you are interested in this knowledge, you can refer to the relevant blog or contact us.

Maximum wattage: The maximum output power of an LED driver refers to the maximum power it can provide to the LED module, usually expressed in watts (W). The maximum output power of the LED driver should be able to meet the power needs of the LED lamp, taking into account a certain safety margin. For example, if your lamp is 100W, it is suitable to use EUM-100S105DG (its maximum output power is 100W). Taking ZGSM Falcon series street light as an example, we use 54 chips (6 in series and 9 in parallel), that is, the forward voltage is 35V, and the power supply We choose the output current to be 2.6A, then the power of the LED module = 35V*2.6A = 91W, and then divide it by the power supply itself (about 9%), that is, the final lamp wattage = 91W/0.91 = 100W.

Other functions of LED light power supply(CLO, timer dimming, Zhaga+D4i)

In addition to basic voltage conversion and current control functions, LED light power supply can also have a variety of other functions to provide other functions/performance for LED lamps or be compatible with other devices. These functions include CLO, timer dimming, Zhaga+D4i and other functions.

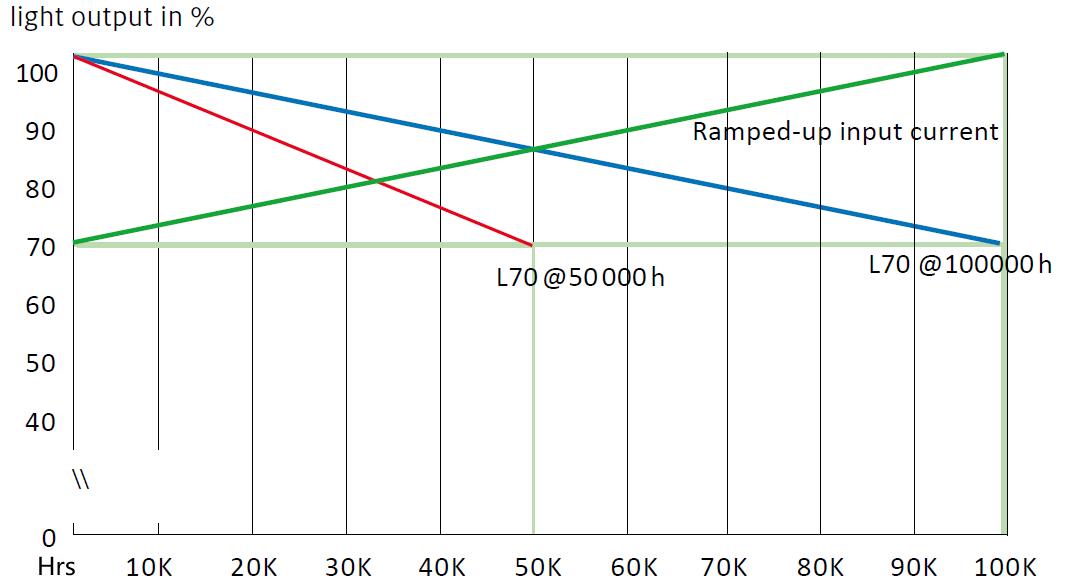

CLO (Constant Lumen Output): It refers to the constant lumen and constant luminous flux output function of LED light power supply. This function allows the output current of the LED driver to be adjusted during the use of LED lamps. This is because during the use of LED lamps, the light efficiency will decrease as the LED lamp chips age, the LED driving performance decreases, and the lens/glass of the lamp becomes contaminated. In order to offset the reduction in luminous flux caused by the reduced light efficiency of the lamp, we need the LED driver to slowly increase the output current during its life cycle to increase the wattage of the lamp to ensure constant luminous flux. This is particularly important for applications that require stable lighting for a long time, such as commercial lighting or outdoor lighting. Through the CLO function, LED lamps can maintain stable light output for a long time to ensure that the application scene can meet the corresponding lighting standards (illuminance, luminance and uniformity) during its project cycle.

Timer Dimming: Timer dimming is a control method for intelligently adjusting the output of LED lamps. It can adjust the brightness of LED lamps according to the needs of a specific time period. This function is usually implemented by LED light power supply, and dimming profiles are often preset in the LED driver according to the brightness level requirements for different time periods to adapt to different environments and needs. In outdoor lighting(road lighting), the traffic flow on the road decreases significantly after midnight, and the lighting demand is not as high as in the first half of the night. Through the timer dimming function, we can lower the wattage of the lamps after midnight to meet the needs of the road’s lighting requirements at this time. This feature can be used to improve energy efficiency and provide suitable light levels for different activity scenarios.

Protection function: LED driver normally provide protection against overvoltage, undervoltage, overcurrent, overheating, and short circuits to ensure the safety of the LED lamp and its power supply circuit.

Zhaga+D4i: Zhaga is an organization focused on the standardization of LED lamp interfaces. It establishes standardized interface specifications so that components such as LED modules, LED light power supplies, lenses, sensors and controllers from different manufacturers can be seamlessly connected, mutually compatible and replaceable. These are very helpful for the development of the LED industry, reducing the cost of LED system development and improving the convenience of installation and maintenance. D4i is a lighting control protocol used to realize communication, control and data transmission between sensors/controllers and LED driving power supplies. Through the D4i protocol, precise control of LED lamps can be achieved, including brightness adjustment, color temperature adjustment, timer switching and other functions. In addition, D4i can ensure data transmission between the controller and the LED driver (lamp). The Zhaga Alliance launched the Zhaga-D4i certification project. Lighting equipment that passes this certification can bear the dual logos of Zhaga and D4i, indicating plug-and-play and interoperability of hardware interfaces and software interfaces. The asset data, power data and operation and maintenance information of the LED power supply are collected through the Zhaga book 20-D4i interface, and the illumination collection function and human presence detection are combined to realize the illumination collection function and human presence perception, and realize automatic control of the lighting system and related data collection and analysis. This series of controllers also supports Bluetooth MESH wireless interface for networking connections between controllers.

Top 5 LED light power supply

There are many manufacturers of LED light power supply, such as world-famous brands such as Philips, Tridonic and Meanwell. Of course, some domestic brands have also risen rapidly in recent years, such as Inventronics, Sosen and Done. The following is a brief introduction to several of these companies.

Inventronics: Inventronics is a company specializing in the design and manufacture of LED lighting drive power supplies. Their products cover a variety of application areas, including indoor lighting, outdoor lighting, industrial lighting and more. The product stability of Inventronics is good, the function is more perfect, the product update is fast, warranty is reliable and the certification is complete.

Philips: As a world-renowned lighting solution provider, Philips not only provides LED lights, it also produces LED drivers, control systems and complete lighting solutions. As well-known companies, their products are more innovative and performance, so their prices are higher.

Meanwell: Meanwell is a professional power supply company whose LED drive power products are used in a wide range of lighting applications. Its product line covers AC/DC, DC/DC converters, DC/AC inverters, etc., but with the change of business direction, its market share of LED light power supply is also decreasing year by year.

Tridonic: Tridonic is a subsidiary of the Odeborg Group, founded in 1956 in Dornbien, Austria. Tridonic is a leading lighting solutions provider in the world, offering a wide range of LED lighting products and systems, including LED drivers, control systems and lighting management software. Their products are widely used in office buildings, retail stores, hotels and restaurants, the education industry, and outdoor lighting.

Dong: Dong is a company specializing in the development, production and sales of LED lighting power supplies. They offer a wide range of LED drive power products covering a variety of application scenarios such as indoor and outdoor lighting. Their products have different specifications to choose from, and the featured features of the power supply are also covered, including timer dimming, constant lumen output and programmable.

ZGSM LED light with different LED light power supply

ZGSM’s lamps are adapted to LED drivers from different suppliers. ZGSM has good cooperation with the above-mentioned LED light power supply manufacturers. If you have questions about LED driver selection and function selection, we can provide you with detailed answers. If you are interested in our lighting fixtures, you can click on the link. These products include street lights, post top lights, gas station lights, stadium lights which can also be with different light power supply options.

Summary

This article mainly introduces what’s LED light power supply and some of its important parameters. These parameters include input specifications, such as input wattage, protection class, THD and PF, etc. Similarly, we have also introduced the output parameters such as output voltage, current, maximum power, etc. In addition to the main parameters above, LED light power supply also has other functions, such as dimming, CLO, timer dimming, Zhaga+D4i, etc. Due to space limitations, this article mainly introduces CLO, timer dimming and Zhaga-D4i. As for other functions such as protection functions, dimming, NTC, etc., which we just briefly mentioned them. If you are interested in these functions, or want to know more about LED light power supply, you can also contact us for more information.

FAQ

Related Posts

Guide for canopy light with battery backup

Tags:

Author

Taylor

Sales Engineer

I am Taylor, with 10 years of experience in lighting sales. Throughout my career, I have developed a deep understanding of the lighting industry and its products. My expertise lies in building strong relationships with clients, understanding their needs, and providing tailored lighting solutions that align with their requirements.